The Pesticide Application Technology Laboratory conducts a combination of laboratory, greenhouse, and field drift trials along with greenhouse and field efficacy trials to understand how to best maximize efficacy from pesticides while minimizing the unintended effects from those applications. The multitude of research generated at the PAT Lab is accomplished by using state-of-the-art equipment and utilizing the lab facilities. Please view the videos below by clicking on the photos to the left to learn more about the various pieces of equipment and technology that make our lab so special.

Tensiometer

The tensiometer allows us to calculate surface tension, evaporation rate, contact angle on a surface (including the leaf surface of different plant species), and a course calculation of absorption rate if necessary. This equipment gives us the ability to understand the fate of a droplet under different environmental conditions (temperature and humidity).

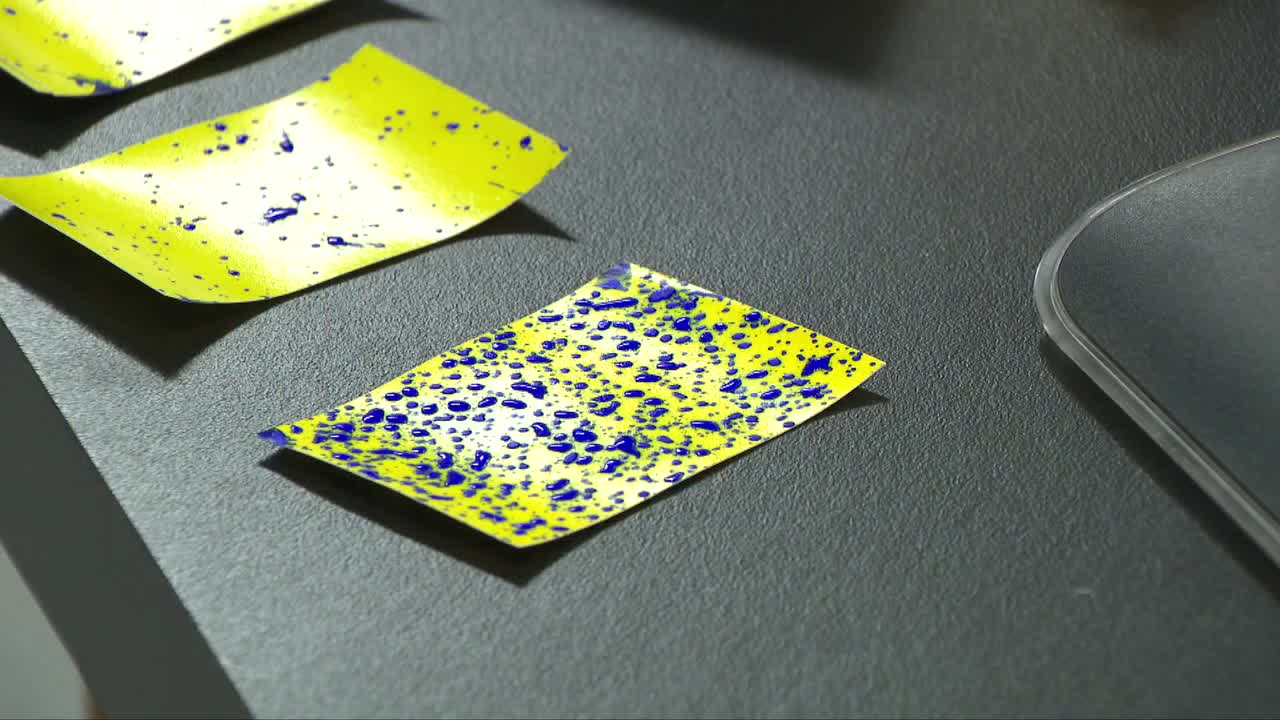

Flat-Bed Scanner & DropletScan

This software is used for scanning water sensitive paper, Kromekote cards or other cards which have visible droplets deposited on them. The program then reports coverage, total number of droplets deposited, and deposition volume (in gallon per acre) giving rapid feedback on application performance.

PAT Lab Greenhouses

The pesticide application technology lab has three greenhouses covering 8,400 square feet. The greenhouses grow crops and weeds that can be sprayed in one of the spray chambers or the low speed wind tunnel to evaluate biological impact from pesticide drift or efficacy of different applications. LED lights in the greenhouse combine red and blue wavelengths that optimizes photosynthesis allowing plants to quicker.

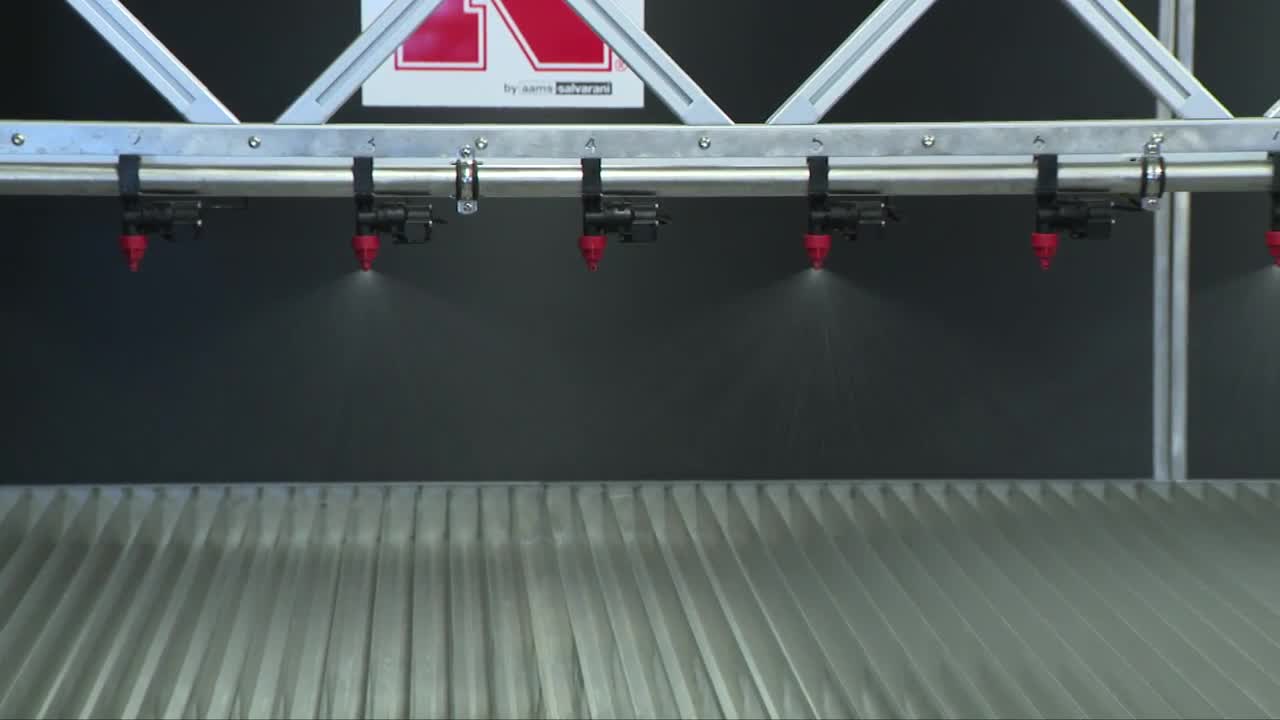

Patternator

The patternator evaluates the consistency of spray distribution across the boom. Spray boom height and pressure can be adjusted to investigate nozzle type and tank solution impact on spray patterns. Sonic measuring devices measure spray volume in each collection tube and calculate a statistical coefficient of variation (CV) to determine uniformity.

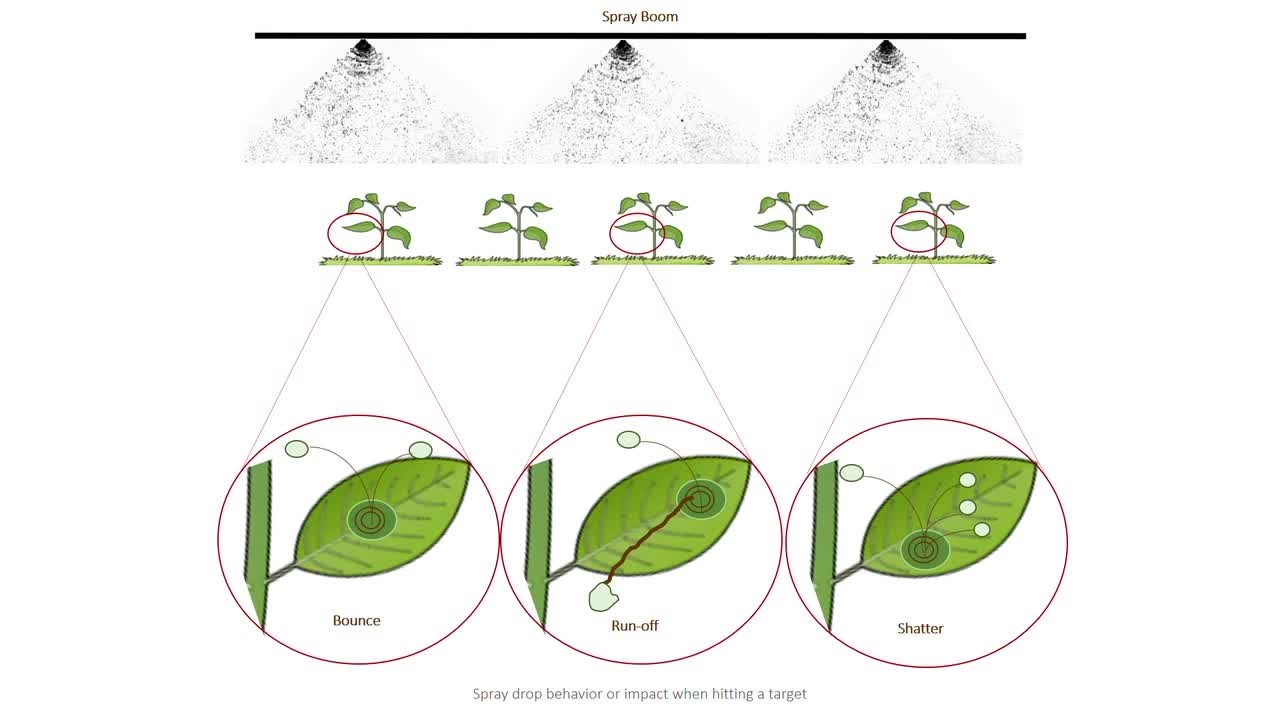

Three-Nozzle Spray Chamber

The three-nozzle research spray chamber is used to make pesticide applications using nozzle designs, spacing, boom heights, pressures, speed and tank solutions similar to those used in the field. The spray chamber allows for rapid comparisons of coverage and efficacy across numerous application parameters.

Single-Nozzle Track Spray Chamber

The Single-Nozzle Track Spray Chamber is used primarily to investigate herbicide efficacy on different weed species. A common application for the single nozzle track spray chamber is herbicide resistance screening with dose response studies. The equipment also features a rain fall simulation function allowing the group to investigate rainfastness and soil activation of pesticides.

Low Speed Wind Tunnel

The low-speed wind tunnel is designed to better understand droplet size and drift potential. The wind tunnel can operate in wind speeds up to 15 mph while capturing droplet size using a laser diffraction instrument. This piece is the iconic mark of the lab and has helped educate applicators on making safer applications with less pesticide drift.